In the industrial world, the smallest overlooked component often becomes the biggest contributor to downtime. Sealing systems are one such example—rarely discussed, yet vital to the integrity and lifespan of machines. From heavy-duty manufacturing equipment to precision instruments, protection against dust, vibration, misalignment and environmental exposure is essential. This is where flexible sealing solutions step in, creating a protective barrier that maintains performance even in demanding environments. Businesses that invest in the right protective components often see improvements in reliability, maintenance intervals, and operational efficiency.

Industry Progress Driven by Reliability

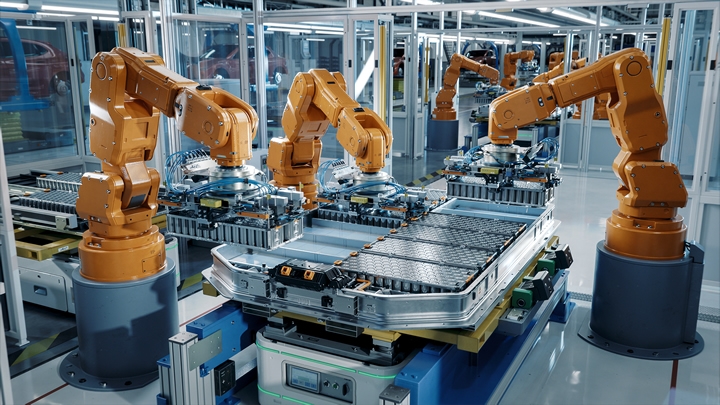

Modern engineering demands components that cope with temperature variation, movement, and constant operational strain. While rigid components serve structural purposes, flexible seal components are engineered to adapt to motion—compressing, expanding, twisting, and bending without failure. Their value becomes especially evident in high-vibration environments like automotive manufacturing, HVAC installations, heavy plant machinery, food processing, and chemical handling. As industries move toward automation and high-precision output, protective seals are becoming more important than ever.

Poor sealing often leads to contaminants entering machinery, leading to wear, leaks, and premature failure. In extreme cases, fluid leaks and air ingress can cause mechanical breakdowns and safety hazards. Investing in high-quality flexible sealing solutions protects equipment, reduces reactive maintenance, and avoids costly operational interruptions. As downtime alone can cost thousands per hour for large facilities, protection is not merely beneficial—it’s strategic.

Material Engineering and Performance

Flexible sealing components are commonly manufactured using specialised polymers selected for resilience, elasticity, and resistance to chemicals and temperature. Materials such as EPDM, silicone, neoprene, nitrile, and natural rubber each serve unique environments. For example, EPDM performs exceptionally in outdoor conditions, resisting ozone and UV, making it suitable for HVAC and exposed mechanical housing. Nitrile is ideal for oil-rich environments common in automotive and hydraulic systems. Silicone, meanwhile, maintains elasticity despite extreme heat or cold, making it a favourite in sensitive or high-temperature applications.

As industries continue to push boundaries—higher speeds, higher pressures, and more compact mechanical designs—material science adapts with innovative compounds. This means more durable, more versatile seals that increase machine longevity and reliability. It also allows custom shaping, thickness variation, and design flexibility to fit bespoke manufacturing systems.

A Practical Example in Application

In many systems requiring movement isolation and environmental protection, flexible components help maintain a sealed interface where rigid materials would otherwise fail. For example, rubber bellows offer an ideal balance of flexibility and protection, often used to shield shafts, rods, and mechanical joints. Their accordion-style shape allows extension, compression, and angular movement while blocking dust, moisture, and abrasive materials. When designed well, they extend component life and reduce maintenance oversight.

Efficiency and Cost-Saving Potential

Business leaders often evaluate sealing components only by unit cost, but the true value lies in lifecycle savings. The total cost of ownership includes installation, maintenance frequency, asset life expectancy, and unplanned downtime prevention. A better quality seal—one designed to withstand specific pressures, chemicals, or outdoor exposure—may cost slightly more at purchase but returns significantly more over time.

Upgrading protective sealing components can also contribute to energy efficiency. Proper sealing reduces leakage in pneumatic and hydraulic systems, improves thermal insulation, and prevents unnecessary strain on motors and pumps. For factories focused on sustainability targets, this becomes another layer of operational advantage. Reduced friction, fewer replacements, and less waste all contribute to better carbon performance.

Industry Insight and Recent Developments

Manufacturers across the globe are increasingly prioritising equipment protection and maintenance-optimised design. With automation accelerating and production volumes rising, the demand for durable sealing components is growing. Recent articles highlight the increasing adoption of advanced materials in manufacturing as industries prepare for demanding future workloads. Analysts note that resilient component design is becoming a pillar of industrial strategy rather than a maintenance add-on.

As supply chains evolve and new environmental pressures emerge, we are likely to witness further growth in high-performance sealing solutions across multiple sectors—from construction and engineering to energy production and medical devices. Businesses embracing smart component selection now will recognise long-term reliability gains later.

Future Outlook

The next decade of industrial engineering will continue to reward durability and efficiency. Components that protect machinery from mechanical stress, environmental exposure, and particulate intrusion will rise in importance. Flexible sealing solutions enable smoother operation, protect assets, and reduce maintenance costs—making them integral to productivity-focused businesses. By valuing component quality and material suitability, operations become more resilient and predictable. In a competitive world, reliable machines deliver reliable profit.